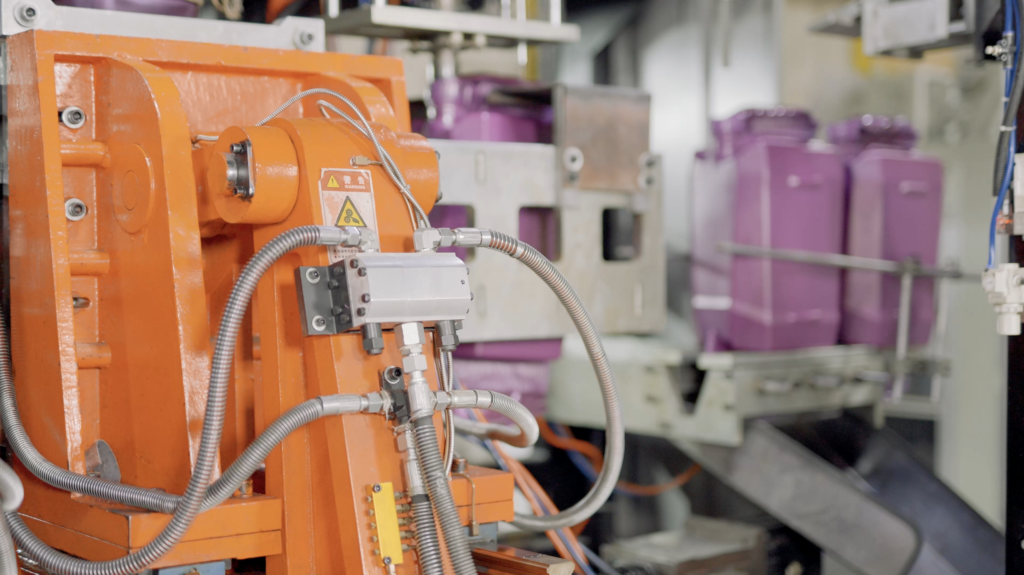

At Pak Form Alborz, we manufacture a wide range of packaging solutions using advanced technologies in Blow Molding, Injection Molding, and Injection-Blow Molding. Our products are designed to meet the diverse needs of industries such as food and beverages, chemicals, pharmaceuticals, cosmetics, lubricants, and detergents.

In our industrial factory, we maximize the quality and efficiency of our products by using the most advanced technologies.

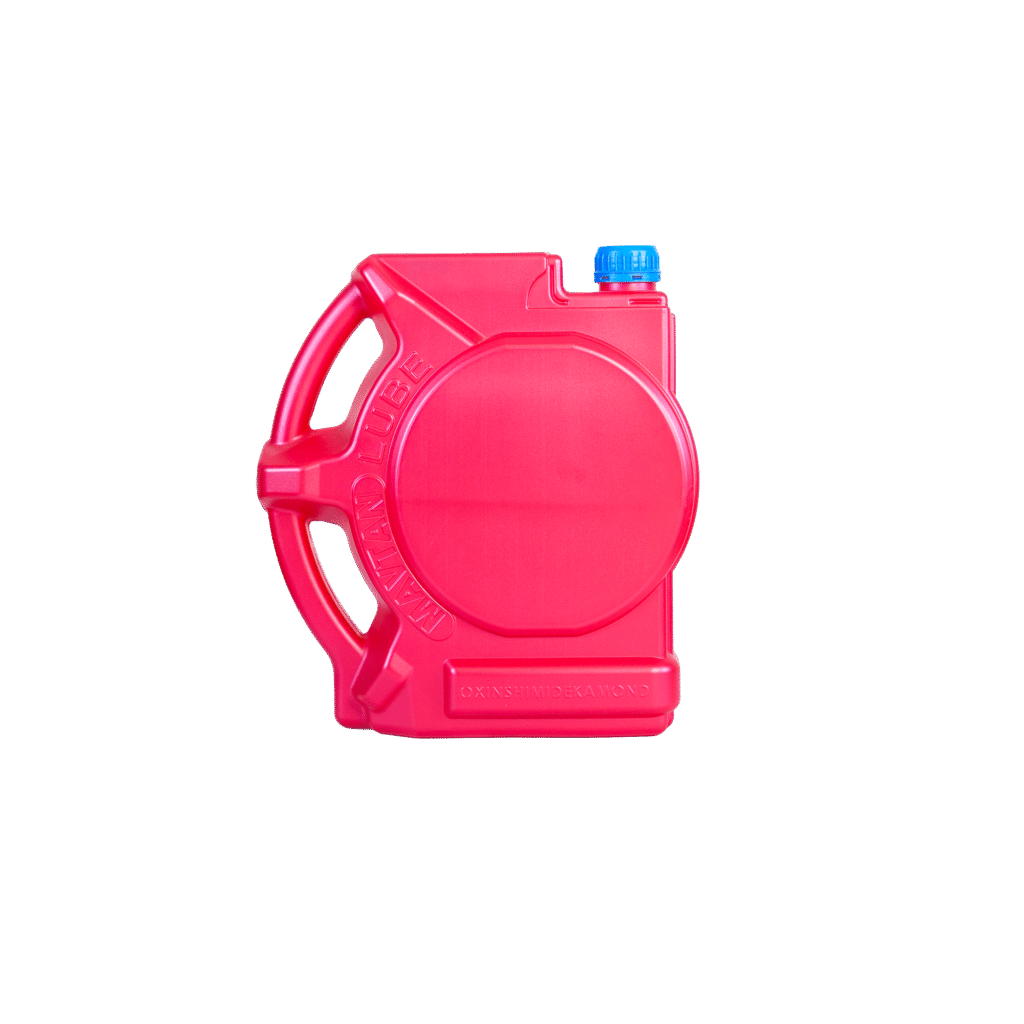

Production of various plastic bottles and containers using blow molding technology. These products feature high durability, excellent chemical resistance, and multi-layer production capabilities, making them ideal for hygiene, food, petrochemical, and lubricant industries. Examples: 1L to 25L bottles, industrial containers, detergent packaging

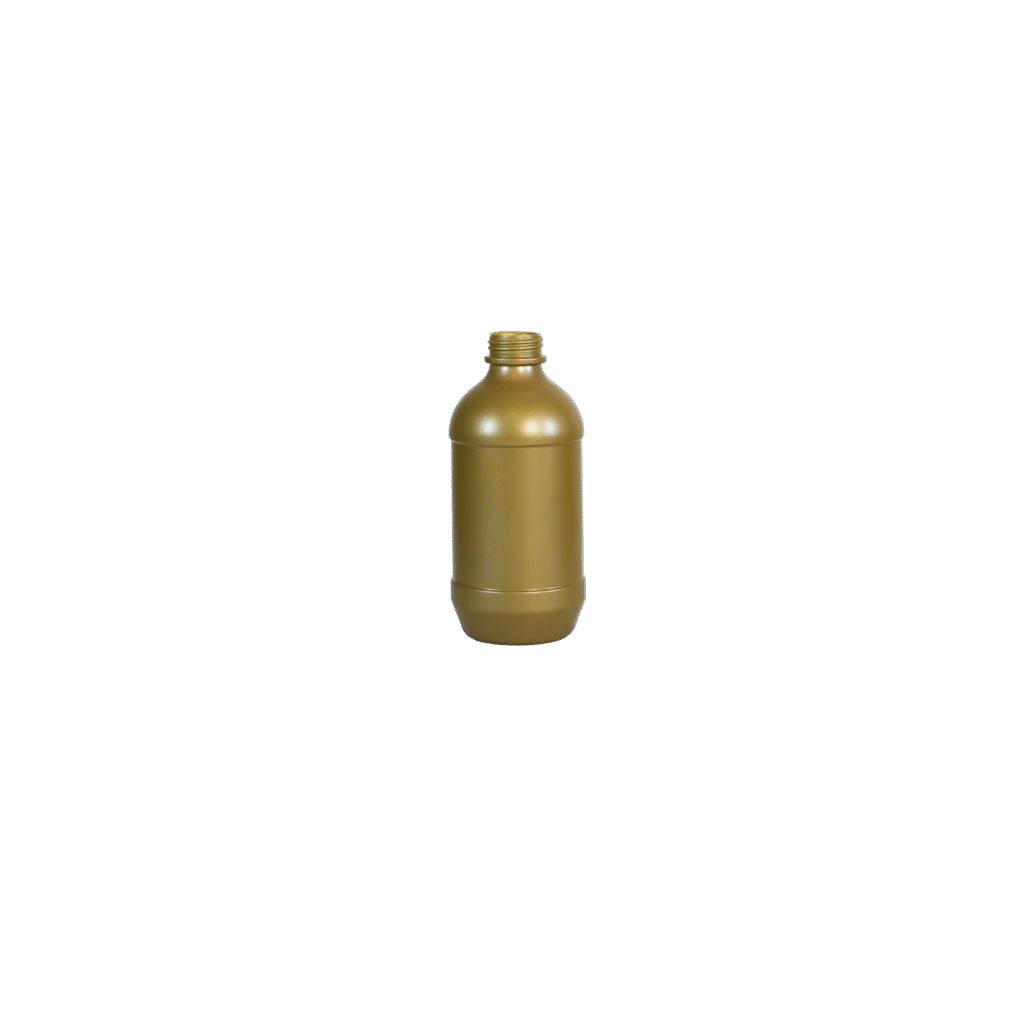

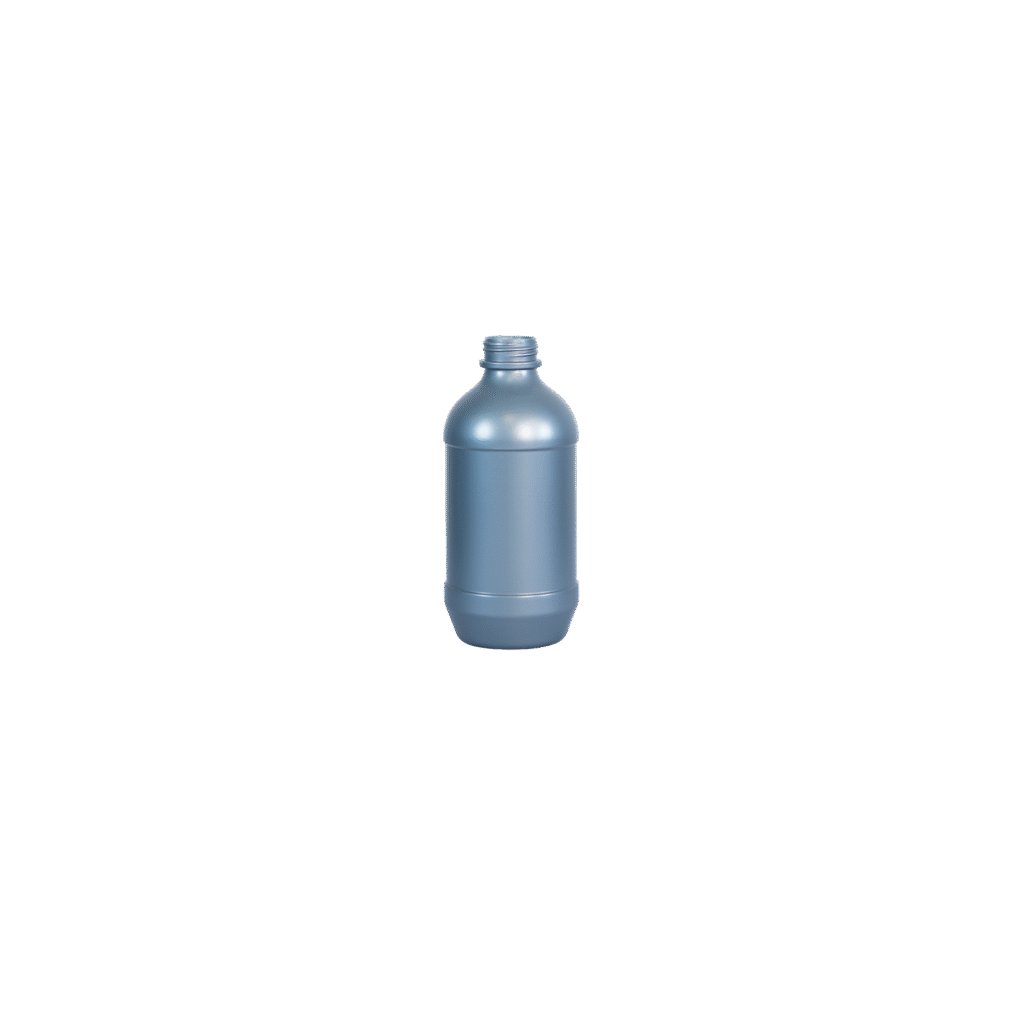

A combination of two technologies for producing stronger products with high precision and uniform wall thickness control. This method is ideal for manufacturing small and specialized bottles that require higher quality standards. Examples: Pharmaceutical and cosmetic bottles, specialized chemical packaging

A combination of two technologies for producing stronger products with high precision and uniform wall thickness control. This method is ideal for manufacturing small and specialized bottles that require higher quality standards. Examples: Pharmaceutical and cosmetic bottles, specialized chemical packaging

Production capacities ranging from 100 ml to 30 liters

These products are designed for thin-walled, durable containers with an optional transparent sight line. The precision in wall thickness distribution ensures superior mechanical and chemical resistance.

Combining the precision of injection molding with the shape flexibility of blow molding

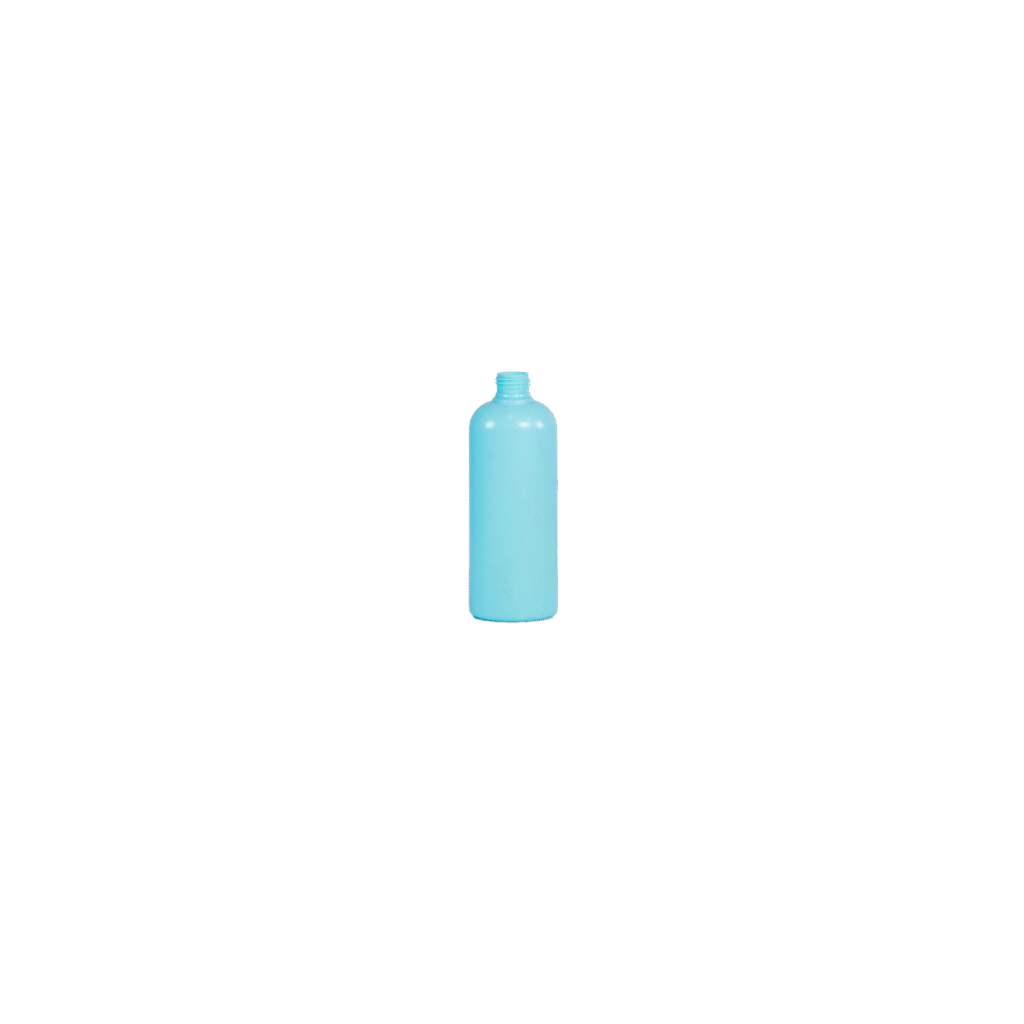

This process is ideal for producing bottles with precise neck dimensions and lightweight, smooth bodies — commonly used in cosmetic, pharmaceutical, and personal care packaging.

5–250 ml: Dropper bottles, medical containers, essential oil packaging

250–1000 ml: Specialty bottles for sanitizers, personal care, and specialty chemicals

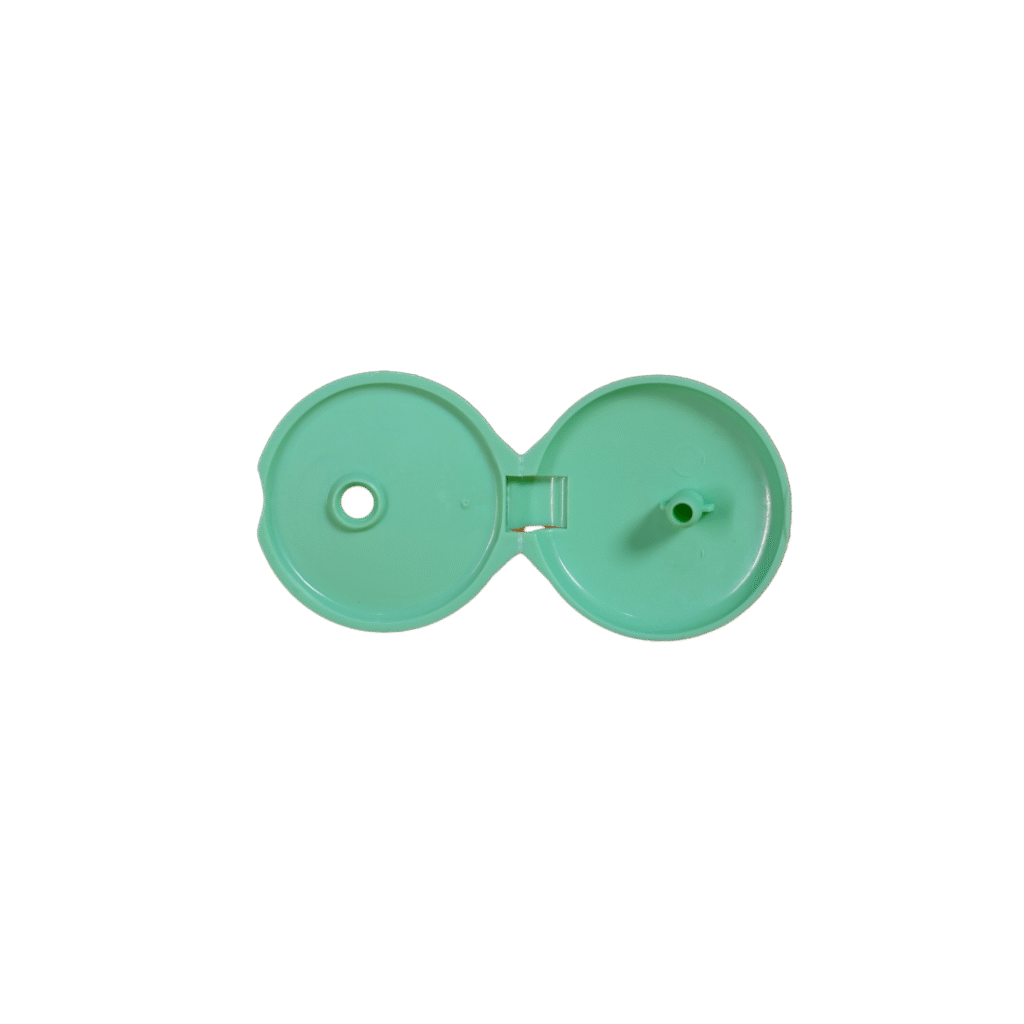

1–50 g: Bottle caps, seals, plugs, and small parts

50–200 g: Handles, connectors, and intermediate parts

200–500 g: Heavy-duty mechanical parts, industrial-grade components

© Copyright for Pak Form Alborz Company